Buck Power Module: Efficient Step-Down Voltage Conversion for Modern Electronics

May 13,2025

By:Epoch

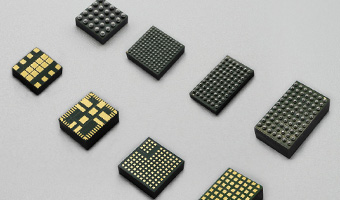

A buck power module is a compact, integrated solution designed to efficiently convert a higher DC voltage to a lower DC voltage, making it essential in a wide range of electronic systems. As the demand for reliable, space-saving, and high-performance power supplies grows, buck power modules are increasingly favored in applications spanning consumer electronics, industrial automation, automotive systems, and data centers.

What is a Buck Power Module?

A buck power module is a type of DC-DC step-down converter that integrates the core components-such as the controller, power MOSFETs, inductor, and often other passive elements-into a single, easy-to-use package. This high level of integration simplifies the design process, reduces the bill of materials, and ensures consistent performance and reliability.

How Does a Buck Power Module Work?

At its core, a buck power module operates by rapidly switching a high-side transistor on and off, controlling the flow of current through an inductor. When the switch is on, current flows through the inductor, storing energy in its magnetic field. When the switch turns off, the inductor releases this energy to the load, maintaining a steady output voltage lower than the input voltage. Output capacitors smooth the voltage, ensuring minimal ripple and stable power delivery.

Key Features and Benefits

· High Efficiency: Buck power modules often achieve efficiencies above 90%, minimizing power loss and heat generation compared to linear regulators.

· Compact Solution Size: By integrating the converter, inductor, and other passives, these modules offer the smallest possible footprint, ideal for space-constrained designs.

· Simplified Design: With fewer external components required, engineers can accelerate development, reduce design complexity, and lower the risk of errors.

· Reliable Performance: Factory-qualified internal components ensure robust thermal management, EMI optimization, and operational stability.

· Protection Features: Many modules include overcurrent, overvoltage, and short-circuit protection, enhancing system safety.

Typical Applications

· Consumer Electronics: Powering CPUs, memory, and peripherals in computers and mobile devices.

· Industrial Automation: Providing regulated power to sensors, controllers, and actuators.

· Automotive Systems: Supplying stable voltage for infotainment, lighting, and advanced driver-assistance systems (ADAS).

· Data Centers: Delivering efficient power conversion for servers and networking equipment.

Buck Power Module vs. Discrete Buck Converter

Feature | Buck Power Module | Discrete Buck Converter |

Integration | High (controller, inductor, passives inside) | Lower (external inductor, passives) |

Design Complexity | Low | Moderate to High |

Solution Size | Smallest | Small to Medium (depends on layout) |

EMI Optimization | Factory-optimized | Depends on designer’s layout choices |

Design Flexibility | Less (pre-set components) | More (customizable components) |

Time to Market | Faster | Slower |

Total BOM Cost | Higher | Lower |

Buck power modules are ideal for projects where ease of use, fast development, and compact size are priorities, while discrete buck converters may be chosen for highly customized or cost-sensitive designs.

The buck power module is a cornerstone of modern power management, delivering efficient, reliable, and compact voltage conversion for today’s electronic systems. By integrating key components and optimizing performance, these modules simplify design, reduce development time, and support the evolving needs of industries focused on miniaturization and energy efficiency.