Incremental Optical Encoder: Precision Motion Feedback for Industrial Automation

Apr 17,2025

By:Epoch

An incremental optical encoder is a critical component in modern motion control, providing real-time feedback on position, speed, and direction for a wide range of automation and servo motor applications. Renowned for their high resolution, reliability, and cost-effectiveness, incremental optical encoders are widely used in robotics, CNC machines, packaging, printing, and more.

What Is an Incremental Optical Encoder?

An incremental optical encoder is a sensor that converts the mechanical rotation of a shaft into a series of electrical pulses. These pulses are generated as an optical disc, marked with alternating transparent and opaque segments, rotates between a light source and a photodetector. Each pulse corresponds to a specific increment of movement, allowing precise measurement of relative position and speed.

How Does an Incremental Optical Encoder Work?

· Optical Sensing:

The encoder contains a rotating disc with slots or lines. As the shaft turns, light passes through these slots and is detected by sensors. The resulting interruptions in light create a stream of digital pulses.

· Signal Output:

Most incremental optical encoders generate two output signals (A and B) in quadrature—meaning they are 90° out of phase. This allows the control system to determine both the amount and direction of movement.

· Reference Pulse:

Many models include a third output (Z or Index), which emits a single pulse per revolution to indicate a reference or home position.

Key Features of Incremental Optical Encoders

· High Resolution:

Available in a wide range of resolutions, typically from 1,000 to 5,000 counts per revolution (CPR), supporting applications that demand fine motion control.

· High Frequency Response:

Capable of tracking high-speed rotations with response frequencies up to 500 kHz and operational speeds up to 6,000 rpm.

· Differential Output:

Provides robust signal integrity and noise immunity, ideal for industrial environments.

· Wide Operating Range:

Designed to operate reliably in temperatures from –20°C to +105°C and in environments with high vibration and shock.

· Cost-Effective and Simple Integration:

Simpler and more affordable than absolute encoders, making them suitable for a broad spectrum of automation tasks.

Applications of Incremental Optical Encoders

Incremental optical encoders are used wherever precise motion feedback is required, including:

· Servo motor feedback in robotics and CNC machinery

· Conveyor speed and position control in packaging and material handling

· Print registration in printing presses

· X-Y positioning in testing and inspection systems

· Medical equipment and laboratory automation.

Advantages and Limitations

Advantages:

· Real-time feedback for high-speed applications

· High resolution and accuracy

· Simple, robust design

· Easy to integrate with most motion control systems.

Limitations:

· Provides only relative position; requires a reference or home position after power loss

· Sensitive to contamination (optical models), though magnetic variants offer better resilience.

Incremental vs. Absolute Encoders

Feature | Incremental Optical Encoder | Absolute Encoder |

Position Feedback | Relative (requires reference) | Absolute (unique code for each position) |

Power Loss Recovery | Needs re-homing | Retains position data |

Cost | Lower | Higher |

Complexity | Simpler | More complex |

Typical Applications | Speed, direction, and relative motion | Safety-critical, multi-turn, and position-critical systems |

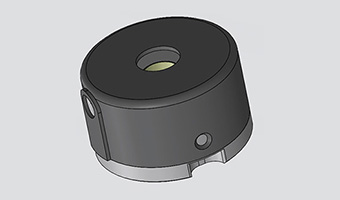

EPOCH ELECTRONIC: Your Partner for Reliable Incremental Optical Encoders

EPOCH ELECTRONIC specializes in supplying high-quality incremental optical encoders for servo motors and automation systems. Our UZ Series bearing incremental encoders deliver high resolution, robust differential output, and reliable performance in demanding industrial environments. Whether you need precise speed control, accurate positioning, or seamless integration with your servo drives, our solutions are tailored to meet your needs.

> Contact EPOCH ELECTRONIC today to find the ideal incremental optical encoder for your automation project and experience the difference in precision and reliability.