Magnetically Integrated Power Module: Compact Power, Maximum Efficiency

May 07,2025

By:Epoch

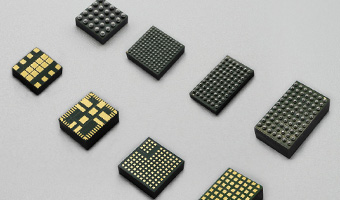

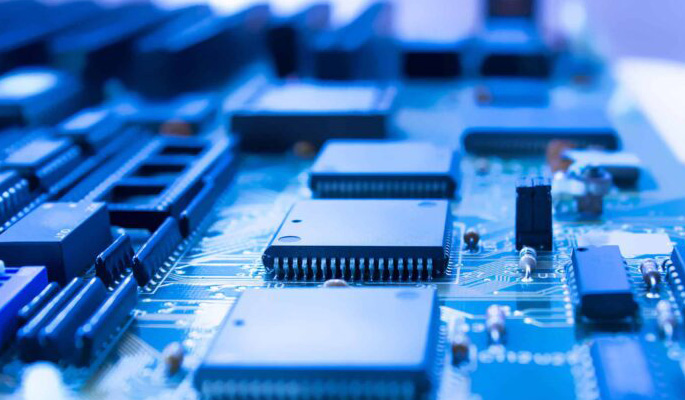

A magnetically integrated power module is a breakthrough in power electronics, combining advanced semiconductor technology with integrated magnetic components-such as inductors-inside a single, compact package. This integration delivers higher power density, superior efficiency, and simplified design, making these modules ideal for today’s demanding applications in data centers, industrial automation, telecommunications, and more.

What Is a Magnetically Integrated Power Module?

A magnetically integrated power module incorporates both the power conversion circuitry and the magnetic components (typically inductors) into one package. By embedding the inductor directly with the power IC, these modules eliminate the need for bulky external magnetics, reduce parasitic losses, and shrink the overall solution size.

Key Advantages

· Ultra-High Power Density

Integrating the inductor and controller allows for up to 23% smaller modules compared to traditional designs, enabling designers to fit more power into less board space.

· Improved Efficiency & Thermal Performance

Proprietary magnetic materials and optimized package design minimize both DC and AC losses, resulting in up to 2–4% higher efficiency and lower thermal resistance. This leads to cooler operation and a higher safe operating area, even under heavy loads.

· Reduced EMI (Electromagnetic Interference)

The close coupling of magnetic and electronic components, along with advanced shielding, reduces both radiated and conducted EMI, making compliance with EMC standards easier.

· Simplified Design & Faster Time-to-Market

With the inductor and other passives pre-selected and integrated, engineers can avoid complex component matching and PCB layout challenges, accelerating development cycles.

Typical Applications

· Data Centers & Servers:

High current, high-density power delivery for CPUs, GPUs, FPGAs, and ASICs, where board space and efficiency are critical.

· Industrial Automation:

Motor drives, PLCs, and robotics benefit from compact, reliable power modules with robust thermal and EMI performance.

· Telecommunications & Networking:

Powering optical modules, switches, and routers where low noise and high reliability are essential.

· Consumer & Portable Electronics:

Smartphones, tablets, SSDs, and IoT devices leverage the small footprint and high efficiency for longer battery life and thinner designs.

Featured Products & Performance

Part Number | Output Current | Input Voltage Range | Output Voltage | Efficiency | Dimensions (mm) | Key Features |

FHT4644 | 4A | 4–15 V | 0.8–5.5 V | 92% | 9×15×4.32 | Multi-channel, parallel operation |

FHT4630 | 2×18A/36A | 4.5–15 V | 0.6–1.8 V | 94% | 16×16×4.32 | Dual/parallel, remote sense |

FHT3860 | 6A | 2.3–5.5 V | 0.5–3.3 V | 94% | 4×6×1.6 | Power Good, soft start |

FHT23030 | 3A | 4.5–17 V | 0.9–6 V | 94% | 3×2.8×1.4 | Constant On-Time, low quiescent current |

FHT8027 | 4A | 5–60 V | 2.5–24 V | 95% | 15×15×4.32 | Wide input, programmable frequency |

These modules use advanced magnetic packaging and proprietary materials to achieve best-in-class size, efficiency, and thermal performance.

Why Choose Magnetically Integrated Power Modules?

· Maximize board space and system flexibility

· Achieve industry-leading efficiency and thermal management

· Reduce EMI for easier compliance

· Accelerate product development with pre-validated, easy-to-use modules

The Future of Power Design

As power demands increase and space constraints tighten, magnetically integrated power modules are redefining what’s possible in power management. By pushing more power into smaller spaces without sacrificing performance, these modules are enabling the next generation of high-performance, energy-efficient electronic systems.

Contact us today to learn more about how magnetically integrated power modules can optimize your next design.