Medium Voltage Buck Power Module: Efficient Step-Down Power Solutions for Industrial and Advanced Applications

May 19,2025

By:Epoch

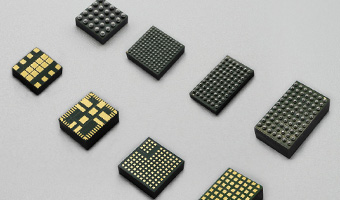

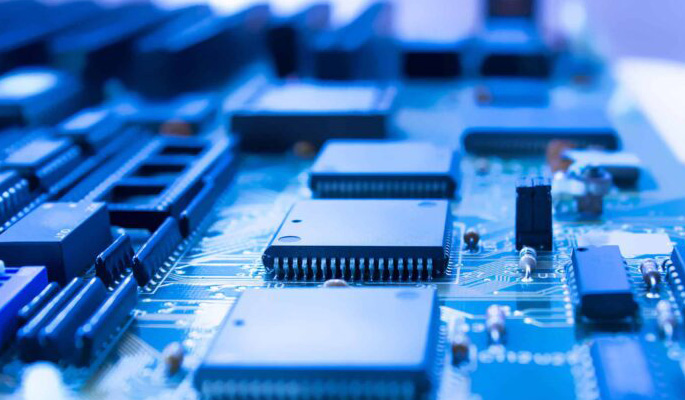

A medium voltage buck power module is a specialized DC-DC converter designed to efficiently step down medium-range DC voltages-typically from around 4.5V up to 40V or higher-to lower voltages required by sensitive electronics. These modules integrate critical components such as power MOSFETs, inductors, and control circuitry into a compact package, delivering high efficiency, reduced design complexity, and reliable performance for demanding applications in industrial control, telecommunications, medical equipment, and more.

What is a Medium Voltage Buck Power Module?

A buck power module is a type of step-down converter that reduces a higher input DC voltage to a lower output voltage while increasing current capacity. The "medium voltage" classification generally refers to input voltages in the range of approximately 4.5V to 40V, bridging the gap between low-voltage portable electronics and high-voltage industrial power systems.

Unlike discrete buck converters, medium voltage buck power modules integrate the inductor, power switches, and passive components into a single, factory-tested module. This integration simplifies PCB design, enhances thermal and electromagnetic interference (EMI) performance, and accelerates time to market.

Key Features of Medium Voltage Buck Power Modules

· Wide Input Voltage Range: Typical modules operate from 4.5V up to 18V, 28V, or even 40V, accommodating various power sources such as batteries, industrial power rails, and automotive systems.

· Adjustable Output Voltage: Output voltages often range from as low as 0.6V to 35V, configurable via external resistors, enabling precise voltage regulation for diverse loads.

· High Efficiency: Efficiencies can reach up to 95%, reducing power loss and heat generation, which is critical for compact and thermally constrained designs.

· Integrated Components: Modules include synchronous rectification MOSFETs, inductors, and filtering capacitors, minimizing external component count and simplifying design.

· Protection Features: Built-in protections such as undervoltage lockout (UVLO), overcurrent, thermal shutdown, and short-circuit protection enhance system reliability.

· Compact Size: Surface-mount packages with dimensions as small as 5mm × 3.2mm × 2.2mm enable miniaturized power solutions for space-limited applications.

Advantages Over Discrete Buck Converters

Feature | Medium Voltage Buck Power Module | Discrete Buck Converter |

Integration | High (inductor, MOSFETs, passives integrated) | Lower (external components required) |

Design Complexity | Low (simplified PCB layout) | Higher (component selection and layout needed) |

EMI and Thermal Optimization | Factory-optimized | Depends on designer’s skill |

Time to Market | Faster | Slower |

Efficiency | Up to 95% | Varies, often lower |

Flexibility | Moderate (preset component values) | High (customizable components) |

Size | Very compact | Larger footprint |

Applications of Medium Voltage Buck Power Modules

· Industrial Control Systems: Powering sensors, controllers, and actuators requiring stable, efficient power conversion in harsh environments.

· Telecommunications and Networking: Supplying regulated voltages for network equipment and communication devices with stringent power quality demands.

· Medical Imaging Equipment: Delivering precise and reliable power for imaging modules and diagnostic tools where stability and noise reduction are critical.

· Automotive Electronics: Managing power rails in electric vehicles and advanced driver-assistance systems (ADAS) that operate on medium voltage batteries.

· Renewable Energy Systems: Integrating with solar panels and battery storage systems to regulate intermediate voltage levels efficiently.

Design Considerations

· Output Voltage Setting: Typically configured via external resistor dividers; output voltages above 5.5V may require additional output capacitors to reduce ripple.

· Thermal Management: Higher output voltages and currents increase thermal dissipation; proper PCB layout and heat sinking are essential for reliable operation.

· Input Capacitor Selection: Low ESR ceramic capacitors (X5R or X7R) with sufficient ripple current capability are recommended to maintain stable input voltage and reduce noise.

· EMI Mitigation: Integrated modules are optimized for low EMI, but careful PCB layout and filtering may be required in sensitive applications.

Medium voltage buck power modules provide a highly integrated, efficient, and compact solution for stepping down DC voltages in the 4.5V to 40V range. By combining key power components into a single package with advanced protection and thermal features, these modules simplify design, improve reliability, and accelerate development cycles across industrial, telecommunications, medical, and automotive sectors. As power demands evolve, medium voltage buck power modules will continue to play a critical role in enabling efficient and robust power management solutions.